What Seal is Best for Cryogenic Temperatures?

Cryogenics involves the study of how matter behaves at extremely low temperatures. In some cases, these temperatures might approach absolute zero as liquefied gasses, refrigerants, coolants, low-temperature hydrocarbons and other cryogenic liquids are used to create very cold environments with stable chemical reactions. The Challenges of Cryogenic Sealing One of the biggest challenges in […]

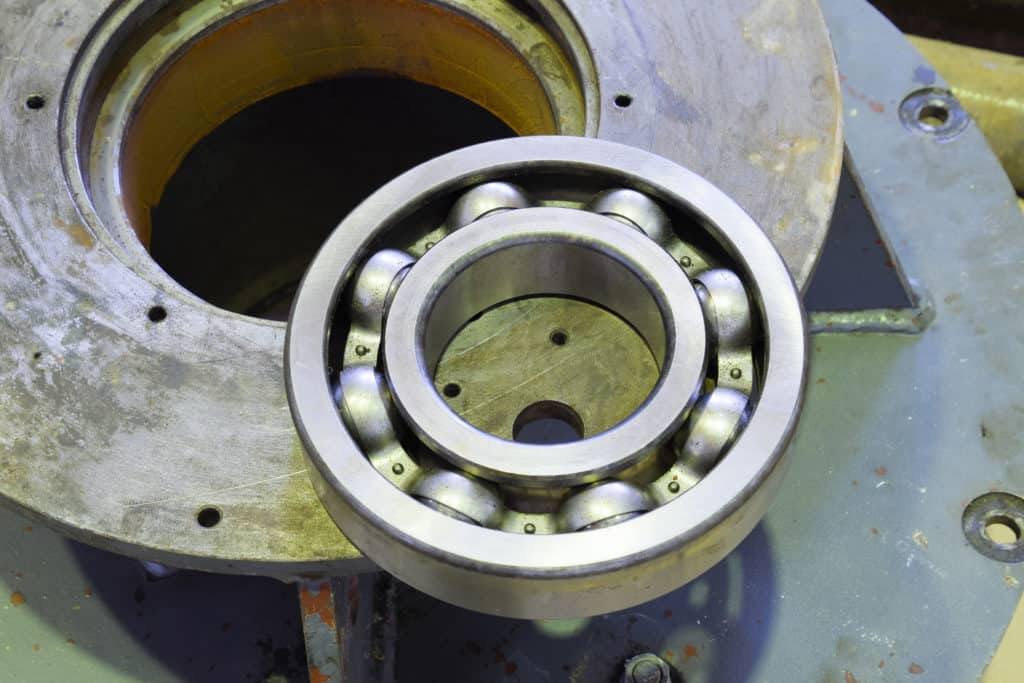

What Effects Does Internal Clearance Have on Bearing Life?

When it comes to maintaining a bearing and maximizing its lifespan, internal clearance is an important factor to understand. If the clearance isn’t right, bearings will not perform efficiently and they will wear out more quickly. What is Internal Clearance? First, it pays to understand what internal clearance represents. In essence, it is the […]

How to Handle Cavitation in Your Application

Cavitation is a serious concern for pump operators. It occurs when miscalibration or other problems cause the formation and subsequent implosion of vapor bubbles within a pump. Cavitation can happen anywhere the pressure of a process liquid falls below it’s ideal vapor pressure. Why is Cavitation a Problem? When cavitation occurs, it can do […]

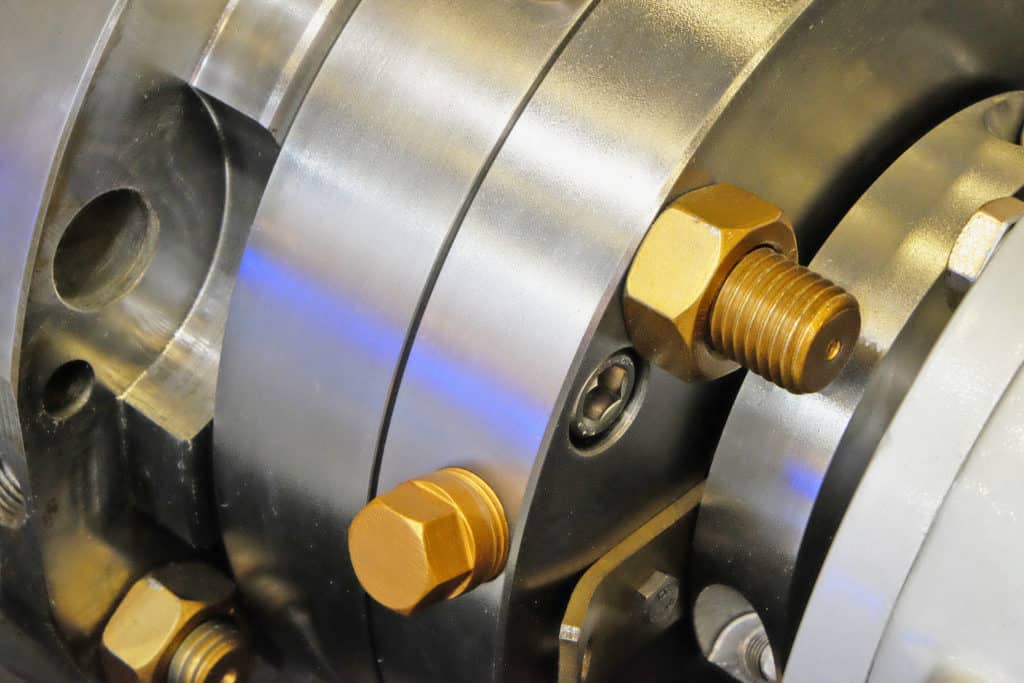

An Unconventional Balancing Method for Your Mechanical Seals

Mechanical seals are very important in pumps. There are various types of mechanical seals that perform specific functions within a pump. Keeping these seals in good working order is crucial for pump efficiency and equipment longevity. Maintaining proper seal balance is one of the key features of any good maintenance program. What is Mechanical […]

Improving the Performance of Your Motor Drive

Pump technology continues to advance with innovative engineering and the development of specialized equipment to handle specific applications and pump processes. One of the biggest areas where operators can gain efficiency is the pump motor. The motor drive is the heartbeat of any piece of equipment. When it is properly configured, customized, operated and maintained, […]

6 Practices to Help You Manage Leaks More Efficiently

If you have a leak in your pump system, it’s bad news. Whether it’s a leaking valve, pump housing, connector or pipe, there are many concerns that will arise. First, it’s bad for equipment, which is not going to run efficiently. This leads to lost productivity and increased downtime to make repairs. Second, it’s bad […]

How Important is Accurate Flow Measurement?

Whether your operation needs to pump out wastewater or pump in clean water, maintaining an accurate flow rate is vital. Too high of a flow rate can cause pump leaks and various problems. Not enough flow can cripple your productivity. You must have accurate control of the pumps and efficient ways to measure and monitor […]

Improve Longevity with Water-Cooled Hydrodynamic Fan Bearings

When it comes to industrial fans, bearings are extremely important. It is critical to select the right fan bearings and maintain them for improved performance and increase equipment longevity. Hydrodynamic Fan Bearings Water-cooled hydrodynamic fan bearings are being used more and more in large-scale industrial fans, especially in applications with extreme environments. We’re talking […]

7 Tips for Planning a Dewatering Project

Just about every construction and mining operation has to deal with groundwater and surface water. Sometimes you need to recycle and reuse the water, while other times you just need to get rid of it so you can effectively work on the site. There are a lot of important factors to deal with when it […]

The Latest Tech in ANSI Pumps – PumpWorks ANSI Process Pump

Cortech Engineering is proud to offer the latest in ANSI technology: the Pumpworks GEN2 ANSI Process Pump. Featuring 25% more cooling than the GEN1 model and a 5-year unconditional power frame warranty, the PWA GEN2 ANSI Process Pump packs the upgraded features to help extend the life of your pump. All new patent-pending frame […]

How BJM Submersible Pumps Can Be Used in Mining Industry Applications

No matter what you are mining, your operation faces challenges every day. One of the biggest issues for a mining operation is keeping the site dry. For that, you need a submersible pump to move dirty groundwater out of the site. Managing groundwater is a constant battle for a mining operation. If the wrong submersible […]

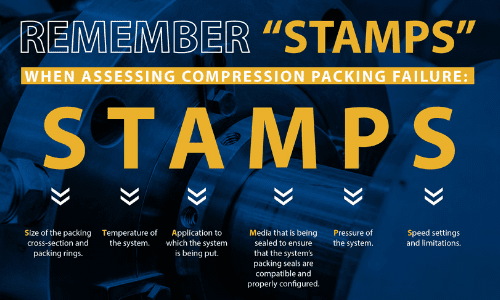

Compression Packing Failure: How to Assess the Problem

Compression packing has been around just about as long as mechanical pumps have existed. This process is still used in today’s equipment to prevent loss of process fluids into the environment. Like most things in the industrial pump world, compression packing is not without challenges. If components aren’t monitored, maintained and repaired as needed, compression […]