Extend Pump Life with These Mechanical Sealing Options

Mechanical seals prevent leaks and the introduction of contaminants between a pump’s rotating shaft and the pump casing. There are many different styles of mechanical seals. They come in all sorts of sizes and configurations to work with different pumps and fluid media. Some are rather simple in design, while others are much more complex. […]

The Advantages of Pumping in Series

Several solutions are available when an application demands higher head than just one standard pump can handle. One option is to replace the pump with a larger, heavier duty model. This certainly makes sense from a performance standpoint. However, the bigger the pump, the higher the cost. Is that kind of upgrade in your equipment […]

What Seal is Best for Cryogenic Temperatures?

Cryogenics involves the study of how matter behaves at extremely low temperatures. In some cases, these temperatures might approach absolute zero as liquefied gasses, refrigerants, coolants, low-temperature hydrocarbons and other cryogenic liquids are used to create very cold environments with stable chemical reactions. The Challenges of Cryogenic Sealing One of the biggest challenges in […]

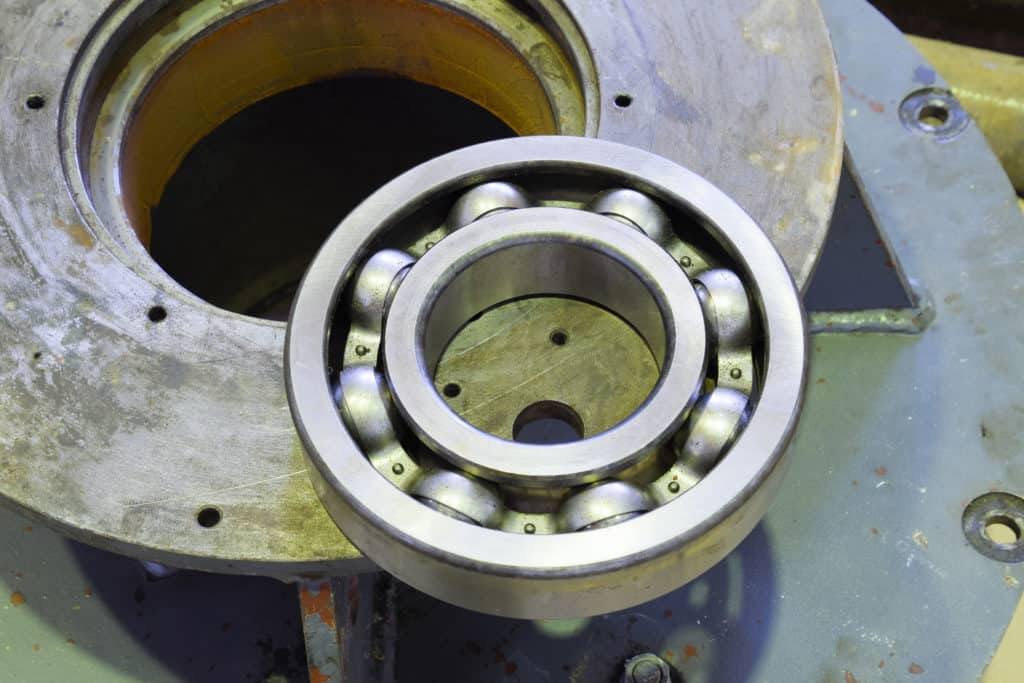

What Effects Does Internal Clearance Have on Bearing Life?

When it comes to maintaining a bearing and maximizing its lifespan, internal clearance is an important factor to understand. If the clearance isn’t right, bearings will not perform efficiently and they will wear out more quickly. What is Internal Clearance? First, it pays to understand what internal clearance represents. In essence, it is the […]

How to Handle Cavitation in Your Application

Cavitation is a serious concern for pump operators. It occurs when miscalibration or other problems cause the formation and subsequent implosion of vapor bubbles within a pump. Cavitation can happen anywhere the pressure of a process liquid falls below it’s ideal vapor pressure. Why is Cavitation a Problem? When cavitation occurs, it can do […]

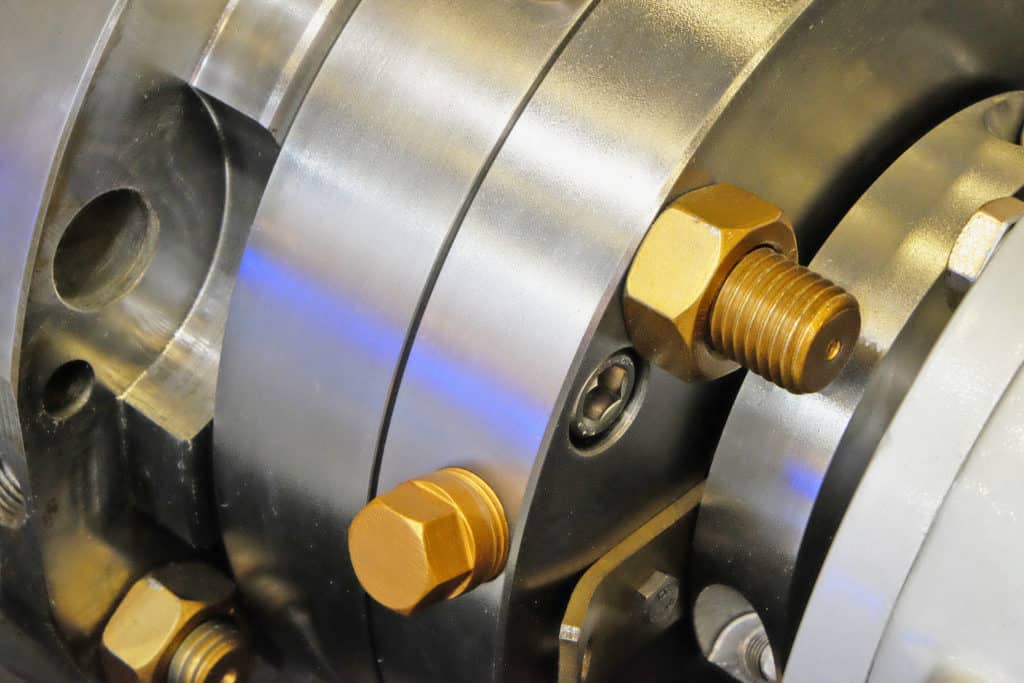

An Unconventional Balancing Method for Your Mechanical Seals

Mechanical seals are very important in pumps. There are various types of mechanical seals that perform specific functions within a pump. Keeping these seals in good working order is crucial for pump efficiency and equipment longevity. Maintaining proper seal balance is one of the key features of any good maintenance program. What is Mechanical […]

Improving the Performance of Your Motor Drive

Pump technology continues to advance with innovative engineering and the development of specialized equipment to handle specific applications and pump processes. One of the biggest areas where operators can gain efficiency is the pump motor. The motor drive is the heartbeat of any piece of equipment. When it is properly configured, customized, operated and maintained, […]

How Important is Accurate Flow Measurement?

Whether your operation needs to pump out wastewater or pump in clean water, maintaining an accurate flow rate is vital. Too high of a flow rate can cause pump leaks and various problems. Not enough flow can cripple your productivity. You must have accurate control of the pumps and efficient ways to measure and monitor […]

The Latest Tech in ANSI Pumps – PumpWorks ANSI Process Pump

Cortech Engineering is proud to offer the latest in ANSI technology: the Pumpworks GEN2 ANSI Process Pump. Featuring 25% more cooling than the GEN1 model and a 5-year unconditional power frame warranty, the PWA GEN2 ANSI Process Pump packs the upgraded features to help extend the life of your pump. All new patent-pending frame […]

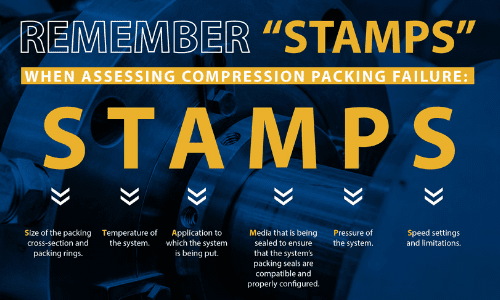

Compression Packing Failure: How to Assess the Problem

Compression packing has been around just about as long as mechanical pumps have existed. This process is still used in today’s equipment to prevent loss of process fluids into the environment. Like most things in the industrial pump world, compression packing is not without challenges. If components aren’t monitored, maintained and repaired as needed, compression […]

The Best Submersible Pumps for Harsh Environments

Though you may use a submersible pump for any number of applications, they often shine the most in challenging environments. Submersible pumps are specifically designed to deal with harsh situations like mines, sewers and other inhospitable places. Every challenging environment brings with it a unique set of needs. Every operation will be a little different. […]

How to Prevent Valve Noise and Flow Damage

Most pump operators and piping system managers are most concerned about leaks and maintaining the desired flow rate. However, two other major issues are valve noise and damage from choked flow or cavitation. Our team at Cortech Engineering has put together a couple of tips you can incorporate into your operation that will help prevent […]